We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Why the CO2 pressure higher is with a Lindr beertap

Why the CO2 pressure needs to be higher with a Lindr beertap?

There is a lot going on about adjusting CO2 pressure for a beertap installation, also a lot of myths. From clients of us we receive the question a lot about adjusting the CO2 pressure for a beertap installation and what the right pressure should be. The right CO2 pressure for your beertap installation is depending on several factors like the sort beerrtap / beertap installation that you are using, but also the diameters of the tubes and cooling coils that are used with your beertap. Other factors are the type of beer that you aare going to pour and ambient temperature.

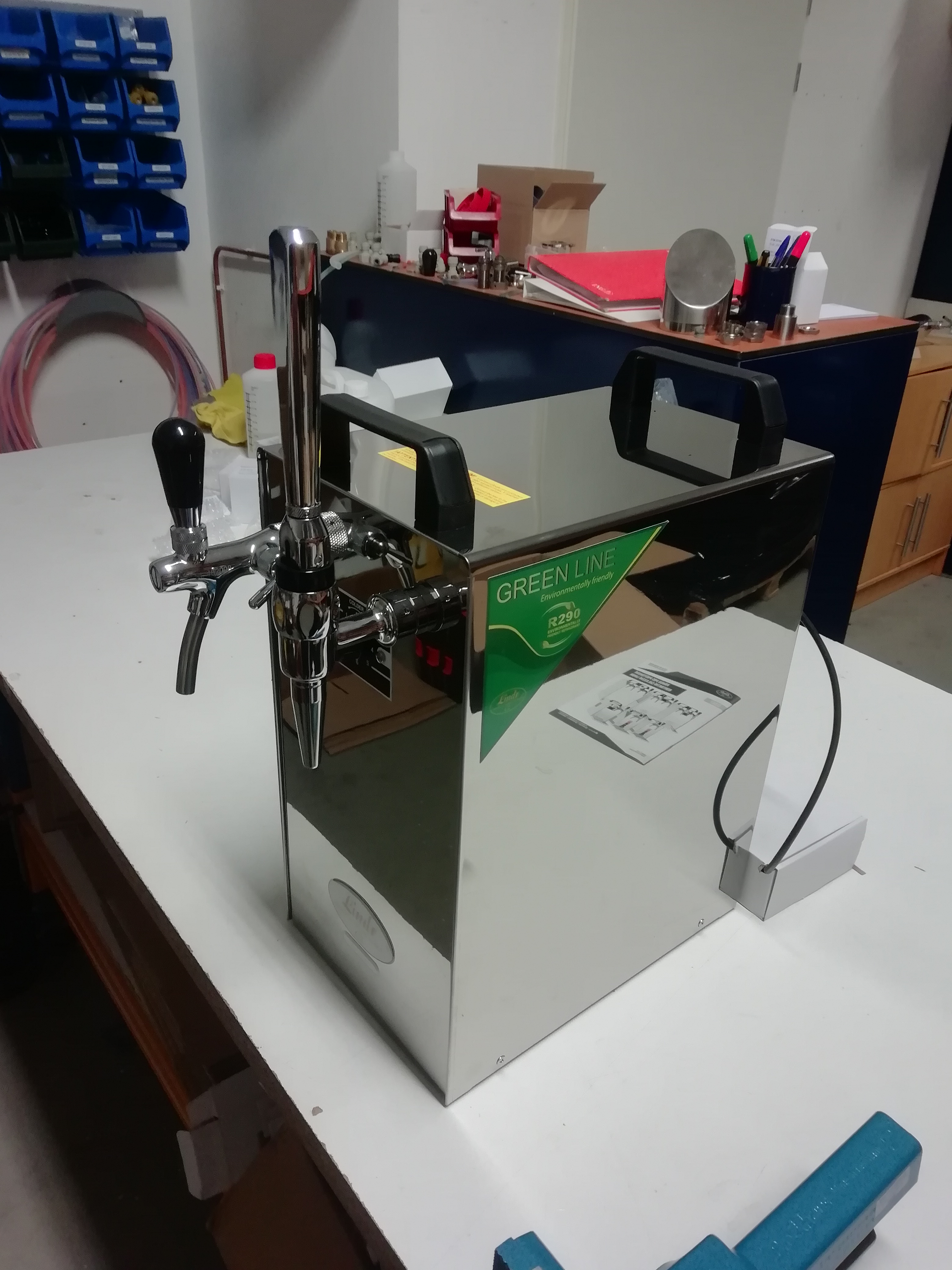

In this article we mainly focus on Lindr beertaps and beertap installations with the standard compensator taps that are used by default on a Lindr beertap / beertap installation. All of the Lindr beertaps and beercoolers are prepared for 3/8" tubes (9,5mm) and have 8mm (outside diameter) cooling coils for the beer. the thinner tubes and cooling coils in combination with the compensator taps give more resistance to your beer than free flow taps with tubes and cooling coils with a bigger diameter that are used a lot with other beertaps and beertap installations. Due to this higher resistance the CO2 pressure needs to be higher with a Lindr beertap / beertap installation. This higher CO2 pressure is necessary for Lindr drycooler beertaps but also for Lindr water cooled beertap installation.

The necessary CO2 pressure for a Lindr beertap / beertap installation is 2.8 bar or higher. Factors on which the CO2 pressure needs to be higher than 2.8 bars are ambient temperature and the type of beer that you are going to pour. When connecting a new keg of beer to your beertap installation the CO2 wants to escape from the beer. The higher the ambient temperature the stronger this reaction will be. To pour a good glass of beer in all these situations you want to counter the process of escaping from CO2 by compressing this process with a higher CO2 pressure. When you are going to pour beers on a warm sunny day a CO2 pressure of 3.2 or maybe even 3.4 bars is completely normal for these situations.

Also pouring special beers can make the use of a higher CO2 pressure necessarily. Special beers like blond beers, tripel beers or other style of craft beers can differ a lot in alcohol and CO2 precentage in the beers. Due to this other alcohol and CO2 percentages the process of escaping CO2 when connecting a keg can be stronger and different with each other type of beer making a higher CO2 pressure necessarily.

Note that these higher CO2 pressures are necessary for a Lindr beertap / beertap installation with the 3/8" (9,5mm) tubes, 8mm cooling coils and standard compensator taps.

Other beertap installation, other CO2 pressure

When you ahve another type of beertap installation like for example a kegerator with a free flow tap your CO2 pressure needs to be much lower. You only have a short transit tube through your dispense tower and a tap with less resistance. Your CO2 pressure in this situation will be in a range from 0.6 to 0.8 bars. Are you using a watercooled beertap installation with a free flow tap and tubes from 1/2" (12.7mm) or even thicker the right CO2 pressure will be in a range from 1.6 and 1.9 bar.

So as you might realise there are a lot of factors that have an impact on the right CO2 pressure. The type of beertap installation in combination with the sort tap, ambient temperature and the type of beer are the most important factors to come to the right CO2 pressure. There is no one size fits all CO2 pressure that is correct for every situation. Hopefully this information will help you to adjust the CO2 pressure for your beertap / beertap installation.

If you still have questions regarding adjusting the right CO2 pressure in your case, don't hesitate to contact us. We are glad to help youo out with that.

Nederlands

Nederlands